The Importance of RFID Tag Selection and Placement

Effective RFID tagging is fundamental to system performance. Simply attaching any tag is insufficient; careful selection and placement are crucial for maximizing value and ensuring reliable data capture.

Selecting the Correct Tag

RFID tags are not one-size-fits-all. They vary significantly in type, frequency, memory, form factor, and environmental resilience. Choosing the right tag is critical for system success.

Passive Tags

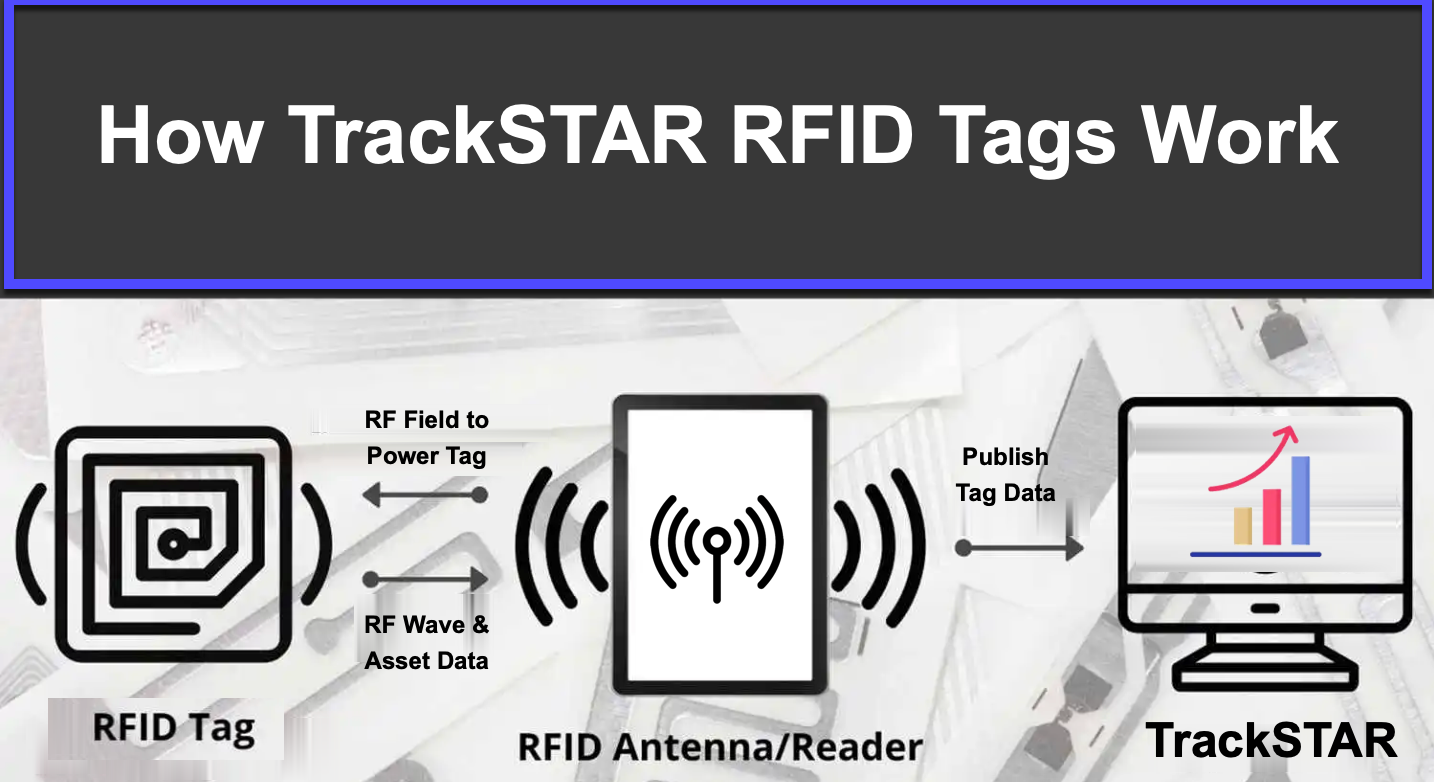

Most common, powered by the reader's RF field. Cost-effective with shorter read ranges. Available in different frequencies (LF, HF, UHF), each with varying range, material penetration, and data speed characteristics.

Active Tags

Battery-powered, offering longer read ranges and potentially more features (like sensors), but at a higher cost and with limited battery lifespan. Ideal for tracking high-value assets over large areas.

Semi-Passive/BAP Tags

Use a battery to power the tag's circuitry (e.g., sensors) but still rely on the reader's signal for communication, offering a balance between range/features and cost/lifespan.

Value Add: Proper Tag Selection

Selecting the correct tag based on application requirements (required read range, environmental conditions, materials, data storage needs, regulatory environment, and budget) is paramount. Using an inappropriate tag leads to poor read rates, data errors, and system failure. For example, a standard UHF tag placed directly on metal will likely fail, whereas a specialized metal-mount tag is designed for this scenario. Choosing a tag with the right memory capacity and features ensures the necessary data can be stored and captured. Correct selection optimizes performance while balancing cost, directly impacting the system's ROI.

Correct Tag Placement

Where and how a tag is attached to an item is as critical as the tag choice itself. Proper placement ensures reliable reads and maximizes the RFID system's effectiveness.

1 Material Interaction

The material being tagged significantly affects RF performance. Metals reflect signals, while liquids absorb them. Use specialized on-metal tags or incorporate air gaps between the tag and challenging surfaces.

2 Orientation

Tag orientation relative to the reader antenna can drastically impact readability, especially for UHF tags which often have directional antennas. Placement should maximize the chance of alignment within the read zone.

3 Environmental Protection

Tags must be placed to withstand the environment they will encounter (e.g., abrasion, chemicals, extreme temperatures). Encased or embedded tags offer better protection for harsh conditions.

4 Consistency

Standardizing placement ensures predictable read performance across all tagged items. This consistency is critical for system reliability, especially in high-volume applications.

5 Embedding

Integrating tags into products or packaging during manufacturing (source tagging) can offer better protection, consistent placement, and added value throughout the supply chain.

Value Add: Strategic Placement

Correct placement maximizes the likelihood of the tag being successfully read when passing through a designated read zone. It ensures reliability and consistency, minimizing missed reads which can disrupt processes and compromise data integrity. Optimal placement overcomes environmental challenges (like metal interference) and ensures the tag survives the product's lifecycle. Consistent, reliable reads stemming from proper placement directly translate to achieving the desired business outcomes, whether it's accurate inventory counts, efficient asset tracking, or seamless process automation.

Key Takeaway

Thoughtful tag selection and strategic placement are non-negotiable best practices. They transform RFID from a technological possibility into a reliable tool that delivers tangible operational value. The success of an RFID implementation depends as much on these seemingly simple decisions as it does on the sophisticated hardware and software that power the system.