Installation Overview

Successfully installing an RFID system requires meticulous attention to detail, bridging the gap between design specifications and a functional, reliable deployment. Adhering to best practices during this critical phase, as outlined in RFID principles and texts, is essential for achieving optimal performance, ensuring safety, and maximizing the system's value.

"The physical implementation of an RFID system is where design becomes reality. Proper installation translates theoretical performance into actual operational value."

Strict Adherence to Site Survey and Design

The foundation of a good installation is the preceding site survey and design documentation. Installation teams must strictly follow the specified locations for readers and antennas. Any deviation, even seemingly minor ones, can significantly alter read zone coverage and negatively impact performance.

The survey identifies optimal mounting points considering potential obstructions, RF interference sources, and necessary coverage patterns. Verify that the physical environment hasn't changed since the survey; if unexpected obstacles or new equipment are present, consult the design team before proceeding.

Hardware Mounting and Placement

Securely mounting hardware is crucial. Readers should be installed in accessible yet protected locations, considering environmental factors like temperature, moisture, and dust. Antennas require precise placement and orientation (azimuth, elevation, polarization) as defined in the design to shape the RF field correctly.

Use appropriate mounting hardware rated for the equipment weight and environment. Ensure antennas are positioned to minimize potential damage from operational activities. Verify clearances and maintain specified distances from metal objects.

Cabling – The Critical Link

Cabling is often underestimated but is vital for signal integrity, especially in passive UHF systems. Always use the low-loss coaxial cable type specified in the design; substituting cheaper, higher-loss cables will directly reduce read range and reliability. Keep antenna cable lengths to the absolute minimum required, as signal loss increases with length.

Adhere to the cable manufacturer's specifications for minimum bend radius. Route cables carefully, protecting them from physical stress, abrasion, and potential crushing. Use appropriate connectors and secure and label all cables clearly at both ends.

Power and Grounding

Reliable power is essential. Determine if readers will use Power over Ethernet (PoE) or direct AC/DC power supplies and ensure the source meets the reader's requirements. Use dedicated or clean power circuits where possible to avoid electrical noise that can interfere with reader operation.

Proper grounding is non-negotiable for both safety and performance. Follow manufacturer guidelines and local electrical codes to ground reader chassis and antenna mounts effectively. Good grounding helps dissipate static electricity and reduces susceptibility to EMI.

Network Integration

Connect readers to the network infrastructure as planned. Configure IP settings (static or DHCP, subnet mask, gateway) according to the site's network policies. Ensure necessary firewall ports are open for communication between readers, middleware, and management platforms.

Verify network connectivity using basic tools like ping tests and confirm the reader appears in the management or middleware software. Document all network configurations for future reference and troubleshooting.

Initial Configuration and Verification

Once physically installed and connected, perform initial reader configuration. Set basic parameters like reader name, time/date, and confirm antenna detection. Set initial transmit power levels, often starting lower and increasing systematically during later testing phases.

Conduct basic post-installation checks: verify power status, network link lights, and attempt a basic tag read test if feasible to confirm fundamental operation before handing over for full commissioning and testing.

Safety First

Installation must comply with all site safety regulations and electrical codes. Ensure equipment mounting is secure and doesn't create physical hazards. Personnel safety should always be the top priority during any installation process.

Key Takeaway

By diligently following these installation best practices derived from established RFID knowledge, organizations ensure their system is physically sound, safe, and ready for the crucial commissioning and testing phases, paving the way for successful long-term operation.

Installation Examples

Below are various real-world RFID installation examples showcasing different types of read zones in various environments. Each installation is tailored to meet specific operational requirements while maximizing read reliability.

Driveway Read Zones

Exterior installations for monitoring vehicle movement through property entrances and exits.

Pole Mount Read Zones

Weather-resistant enclosures mounted on poles for wide area coverage in outdoor environments.

Tractor Trailer Read Zones

Antennas embedded within trailer structures for tracking contents during transportation.

Staging Area Read Zones

Strategic antenna placement for monitoring items in preparation or staging areas.

Crane Read Zones

Specialized installations for tracking materials being moved by overhead cranes in industrial settings.

Warehouse Read Zones

Comprehensive antenna systems for tracking inventory movement throughout warehouse facilities.

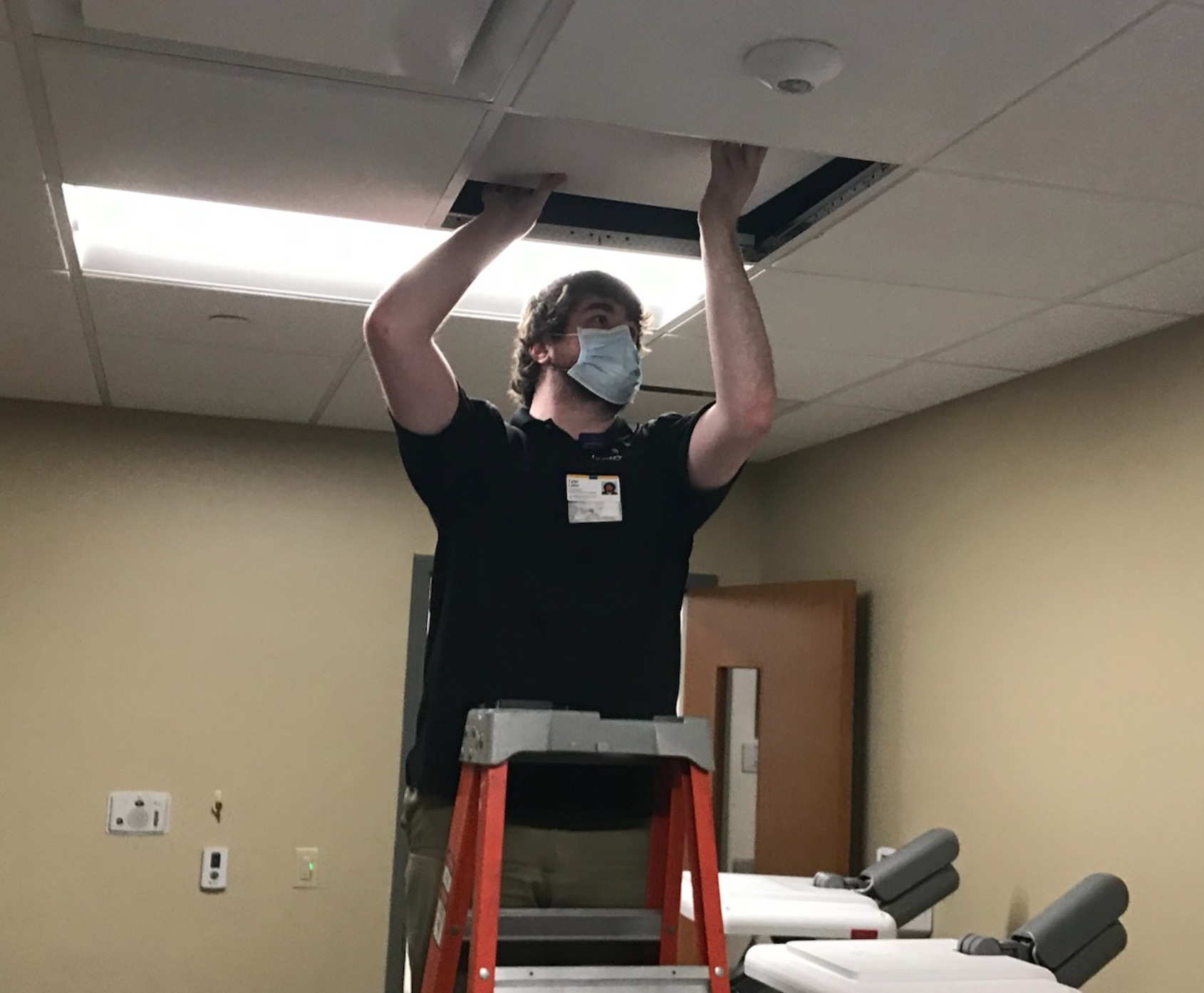

Drop Ceiling Read Zones

Discreet installations above ceiling tiles for unobtrusive monitoring in office or retail environments.

Secure Door Read Zones

Access control installations at doorways for tracking personnel movement and enhancing security.